Hello

….lets continue from here

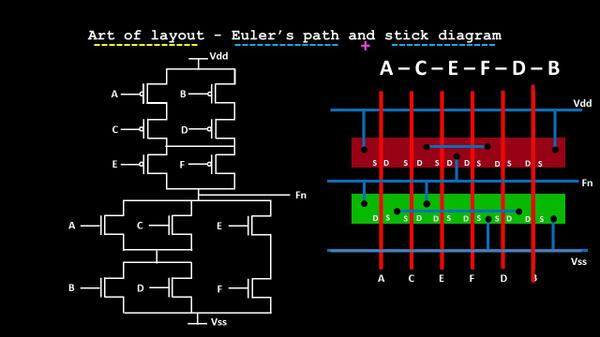

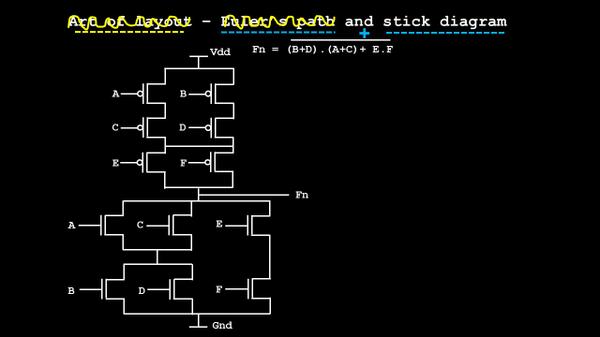

So I have been bragging about that ‘art of layout’ is a combination of euler’s path and stick diagram. But you need a proof why am I saying that

Let’s first find out what happens if we decide to go only by stick diagram and do not take euler’s path into account

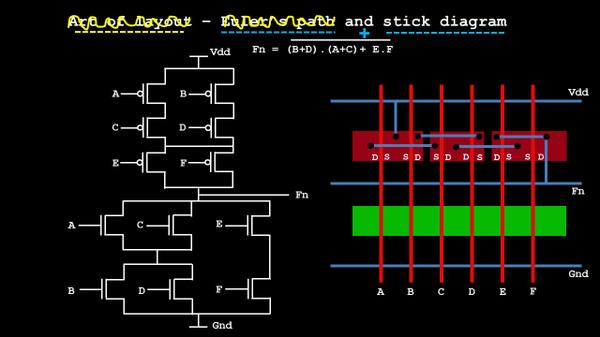

I will go by the rules of stick diagram… first draw supply lines, then output lines, then the pdiffusion, ndiffusion and finally the polysilicon strips in some random order A – B – C – D – E – F. Below is how it will look

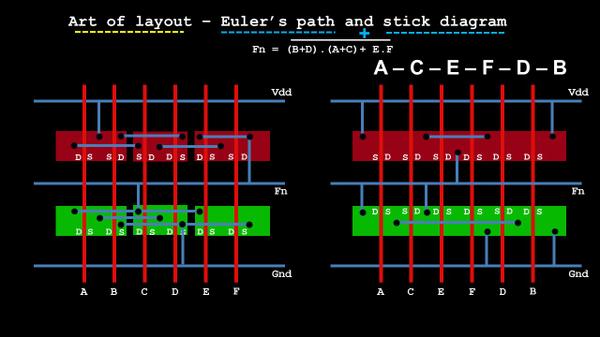

![]()

Then, let’s move further with some rules of stick diagram for connectivity…If you very carefully select the source ‘S’ and ‘D’ region around poly, then most likely, you will end up something like below for pull-up network….. (sentence continued after below image)

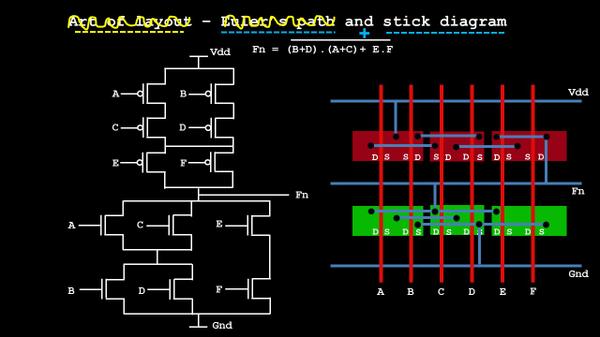

…..(sentence continued from above image)…and you will end up something like below for the pull-down network (you can verify the correctness of connectivity and in case you are looking for concepts on stick diagram, please take up custom layout course from here)

So what do you see here …. the p-diffusion and n-diffusion continuity is miserable, too many breaks, clumsy metal lines, highly congested and complex to fabricate…. This is just a small logic function we are trying to build, imagine what will happen, if we select poly strips in randomness…. just think about the congestion for metal connections, it will be a nightmare to fix DRC’s for such congested design….

Now, what’s the solution to have the most optimized layout in terms of area and performance??? That’s why I call it ‘Art of layout‘, because “Art is not what you see, but what you make others see“

You definitely dont want your fabrication team to look in the above one, but a better one …. Let’s build it using both euler’s path and stick diagram in my next blog ….

Until then …. happy learning!!!!