VSD FPGA Based Maze Solving Robot Design and Development.

VSDSquadron FPGA Mini (FM)

This document presents a detailed walkthrough of building a Maze Solver Bot using the VSDSquadron FPGA Mini (FM) board. It includes essential command-line operations, PCB design schematics, and RTL code implementation, offering a complete view of the hardware and software integration process.

📋 Table of Contents

- Board Overview

- Specifications and Pinouts

- VSDSquadron FM FPGA – Software Installation Guide

- Command Breakdown

- Example Makefile Snippet

- Full Workflow Example

- Tools Typically Used

- Main Commands

- Single Layer – Maze Solver Bot Development

- Double Layer – Maze Solver Bot Development

- Final Output – Working Bot Demo

- Project Recognition

- Project Authors

Board Overview

The VSDSquadron FPGA Mini (FM) is a compact and cost-effective development board designed for FPGA prototyping and embedded system projects. It offers a seamless hardware development experience with an integrated programmer, versatile GPIO access, and onboard memory, making it ideal for students, hobbyists, and developers exploring FPGA-based designs.

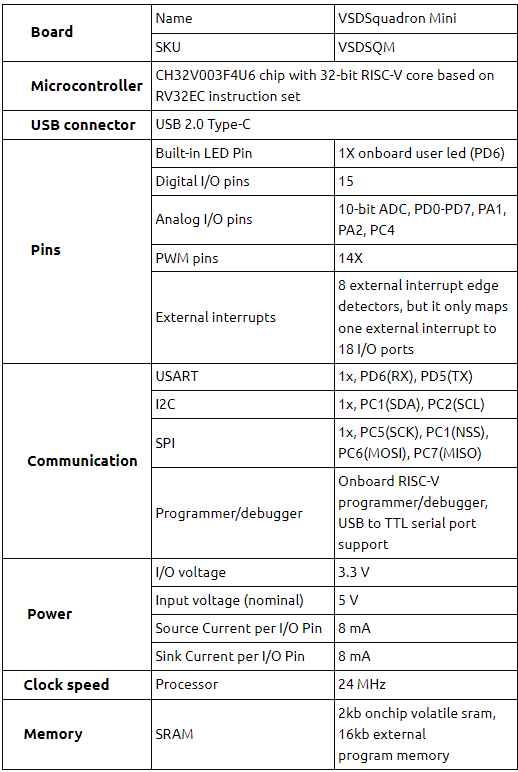

Specifications and Pinouts

- FPGA Chip: Lattice UltraPlus ICE40UP5K

- Logic Cells: 5,280

- SPRAM: 1Mb

- DPRAM: 120Kb

- Multipliers: 8

- GPIO: 32 accessible FPGA GPIOs

- Memory: 4MB SPI flash for data storage and configuration

- LED Indicators: RGB LED for status indication

- Power Regulation: Onboard 3.3V regulators with external supply option

- Dimensions: 57mm x 29mm

| Feature | Specification |

|---|---|

| Technology Node | 40 nm |

| Logic Cells | 5,280 |

| Flip-Flops | 4,960 |

| SRAM Blocks | 120 Kbits |

| DSP Blocks | None |

| Package Type | SG48 |

| I/O Pins | 39 |

| I/O Standards | LVCMOS, LVDS |

| Max Operating Frequency | 133 MHz |

| Clock Sources | Internal oscillator, external clock |

| Core Voltage | 1.2V |

| I/O Voltage | 3.3V, 2.5V, 1.8V |

| Operating Temp Range | -40°C to 85°C |

| Development Tools | Project IceStorm, Yosys, NextPNR |

Prerequisites

Install the following tools before proceeding:

General dependencies

sudo apt-get install git vim autoconf automake autotools-dev curl libmpc-dev \ libmpfr-dev libgmp-dev gawk build-essential bison flex texinfo gperf libtool \ patchutils bc zlib1g-dev libexpat1-dev gtkwave picocom -y

FPGA toolchain (Yosys/NextPNR/IceStorm)

sudo apt-get install yosys nextpnr-ice40 icestorm iverilog -y

Setup

Clone the repository:

cd ~ git clone https://github.com/gowthamnow/VSD-MAZE-ROBOT

📌 Additional Features

- 4MB SPI Flash

- RGB LED indicators

- Onboard 3.3V

- 32 GPIO accessible for prototyping

- Form Factor: 57mm x 29mm, Height: Top 8mm, Bottom 1mm

VSDSquadron FM FPGA – Software Installation Guide

This guide helps you set up the VSDSquadron FPGA Mini (FM) board on your system and run your first project.

📥 Required Software and Resources

- VirtualBox (Download: https://www.virtualbox.org/wiki/Downloads)

- VSDSquadron FPGA Mini (FM) Software Package

- Download Link: https://forgefunder.com/~kunal/vsdsquadron_fpga_mini.zip

- Minimum 100GB free disk space on

C:orD:drive - 4GB RAM and 4 CPU cores recommended

- VDI file provided inside the software package

💻 Installation Instructions (Windows Users)

1️⃣ Check Disk Space

Ensure you have at least 100GB free.

2️⃣ Download and Extract Software

- Download the VSDSquadron software zip package.

- Extract it to a known location.

3️⃣ Install VirtualBox

- Download and install Oracle VirtualBox.

4️⃣ Create a Virtual Machine

- Open VirtualBox → New → Enter details:

- Name: VSDSquadron_FPGA

- Type: Linux

- Version: Xubuntu (64-bit)

- Allocate:

- RAM: 4096 MB

- CPU: 4 cores

5️⃣ Select the VDI File

- In hard disk settings, select: Use an existing virtual hard disk file

- Browse to the extracted .VDI file

6️⃣ Start the Virtual Machine

- Boot the VM and login with:

- Username: vsdiat

- Password: vsdiat

📂 Running the Example Project (Blink LED)

1️⃣ Open Terminal in VM

- Right-click on desktop → Open Terminal

2️⃣ Navigate to Project Folder

cd VSDSquadron_FM cd blink_led

3️⃣ Connect the Board to VM

- Connect FPGA board via USB

- In VirtualBox → Devices → USB → FTDI Single RS232-HS

- Verify connection:

lsusb

- Look for “Future Technology Devices International”

🛠 Programming the Board

Clean previous builds:

make clean

Build binaries:

make build

Flash to FPGA:

sudo make flash

✅ If successful: RGB LEDs on the board will blink.

📝 Troubleshooting:

- If flashing fails, reconnect the board and select Devices → USB → FTDI Single RS232-HS again.

- Retry

sudo make flash.

Command Breakdown

1️⃣ make

Purpose:

Compiles the Verilog design files.

What Happens:

- Runs synthesis and simulation tasks.

- Generates intermediate files like

.json,.vvp, or.bin.

Usage:

make

2️⃣ make build

Purpose:

Builds the design and prepares the FPGA bitstream.

What Happens:

- Maps the synthesized design to FPGA constraints.

- Generates the final FPGA-ready binary or bitstream (e.g.,

top.binortop.bit).

Usage:

make build

3️⃣ sudo make flash

Purpose:

Flashes (uploads) the generated bitstream or binary to the FPGA hardware.

Why sudo?

- Flashing often requires USB/JTAG access, needing root permissions.

Usage:

sudo make flash

Example Makefile Snippet

build:

yosys -p "synth_ice40 -top top -json top.json" top.v

nextpnr-ice40 --hx8k --json top.json --asc top.asc

icepack top.asc top.bin

flash:

iceprog top.bin

Full Workflow Example

make # Synthesize and simulate the Verilog FSM make build # Generate bitstream for FPGA sudo make flash # Flash the bitstream onto the FPGA board

Notes

- Toolchains and flashing commands might vary based on your FPGA board (e.g., iCEBreaker, Arty).

- Replace

iceprogwithopenFPGALoaderorvivadofor other FPGA platforms. - Always check hardware permissions;

sudomay be required for flashing.

Tools Typically Used

- Yosys: Synthesis

- NextPNR: Place & Route

- icepack / Vivado / openFPGALoader: Bitstream generation

- iceprog / openFPGALoader: Flashing to FPGA hardware

Main Commands

| Command | Description |

|---|---|

make | Compile and synthesize Verilog code |

make build | Generate FPGA-ready bitstream |

sudo make flash | Upload bitstream to the FPGA hardware |

Getting Started

- Software Tools Required: Project Icestorm, Yosys, NextPNR

- Programming: Onboard FTDI FT232H enables USB-based programming.

- First Project: A preloaded “blink LED” example is included for quick testing.

Single Layer – Maze Solver Bot Development

You can refer to the following resources related to the single-layer maze bot in the dedicated repository:

- Images of the maze and bot

- PCB Designs used for the single-layer implementation

- Output Videos demonstrating the bot’s working

👉 Click here to visit the Single Layer Maze Development Repository

Double Layer – Maze Solver Bot Development

PCB Design

Schematic Diagram

Below is the complete schematic diagram for the double-layer maze development board. It includes the following circuit blocks:

| Component | Function |

|---|---|

| Voltage Regulator | 5V power supply using LM7805 with external switch |

| VSD Microcontroller Unit | Core control logic and signal processing |

| Motor Driver | Controls left and right motors using ROB-14450 |

| Ultrasonic Sensors (HC-SR04) | Three sensors for obstacle detection |

| Encoders | Wheel encoder input for feedback control |

| Bluetooth Module | Wireless communication |

| LED Outputs | Status indication |

Draftsman Drawing

The following image shows the Draftsman view of our PCB, including:

- Top view of component layout

- Left, right, and back profiles for assembly reference

- Proper alignment and height of all modules

PCB Layout – Top and Bottom Layers

3D View of the PCB

Fabrication and Assembled Bot

Components Used

The following components were used in building the Maze Solver Bot on the VSDSquadron FPGA Mini board:

| S.No | Component | Quantity |

|---|---|---|

| 1 | VSD Squadron FPGA Mini | 1 |

| 2 | TB6612FNG Motor Controller/Driver | 1 |

| 3 | Ultrasonic Sensor Module | 3 |

| 4 | ENCODER N20 Motor | 2 |

| 5 | 5 cm Wheel | 2 |

| 6 | Li-Po Battery 7.4 V 600 mAh | 1 |

| 7 | Capacitor, 2.2 µF | 2 |

| 8 | Capacitor, 100 nF | 1 |

| 9 | LED | 1 |

| 10 | Connector Header Through Hole (3-position) | 1 |

| 11 | Connector Header Through Hole (2-position) | 2 |

| 12 | Female Header 2.54 mm (6-position) | 3 |

| 13 | Female Header 2.54 mm (4-position) | 1 |

| 14 | Female Header 2.54 mm (8-position) | 1 |

| 15 | Resistor, 100 Ω | 1 |

| 16 | Mini SPDT Switch (MINI-SPDT-SW) | 1 |

| 17 | LM7805ACT Positive Voltage Regulator, 5 V | 1 |

| 18 | Mounting Bracket for N20 Micro Gear Motors | 2 |

| 19 | Caster Wheel | 1 |

Tools Used

We used Altium Designer for schematic and PCB design, supported through the Altium Student Lab Program. This tool enabled us to create a precise and industry-grade layout for interfacing the FPGA board with external modules.

FPGA

RTL code

`include "ultra_sonic_sensor.v"

module top (

input wire echo1, echo2, echo3, // Right, Front, Left ultrasonic sensors

output wire trig1, trig2, trig3,

output reg AIN1, AIN2, BIN1, BIN2, // Motor direction control

output wire PWMA, PWMB, // Motor speed control

output wire STBY, // Motor driver standby

output reg led1, led2, led3 // Debug LEDs

);

assign STBY = 1'b1; // Motor always enabled

// -----------------------------------------

// 1. Internal Oscillator (6 MHz)

// -----------------------------------------

wire int_osc;

SB_HFOSC #(.CLKHF_DIV("0b11")) u_SB_HFOSC (

.CLKHFPU(1'b1),

.CLKHFEN(1'b1),

.CLKHF(int_osc)

);

// -----------------------------------------

// 2. Ultrasonic Triggering & Sensing

// -----------------------------------------

wire measure1, measure2, measure3;

refresher250ms refresher1 (.clk(int_osc), .en(1'b1), .measure(measure1));

refresher250ms refresher2 (.clk(int_osc), .en(1'b1), .measure(measure2));

refresher250ms refresher3 (.clk(int_osc), .en(1'b1), .measure(measure3));

wire [15:0] raw1, raw2, raw3;

hc_sr04 sensor1 (.clk(int_osc), .measure(measure1), .echo(echo1), .trig(trig1), .distance_cm(raw1)); // Right

hc_sr04 sensor2 (.clk(int_osc), .measure(measure2), .echo(echo2), .trig(trig2), .distance_cm(raw2)); // Front

hc_sr04 sensor3 (.clk(int_osc), .measure(measure3), .echo(echo3), .trig(trig3), .distance_cm(raw3)); // Left

// -----------------------------------------

// 3. Moving Average Filter (3 samples) - RESTORED

// -----------------------------------------

reg [15:0] sum1 = 0, sum2 = 0, sum3 = 0;

reg [15:0] dist1 = 0, dist2 = 0, dist3 = 0;

reg [1:0] count1 = 0, count2 = 0, count3 = 0;

always @(posedge int_osc) begin

if (measure1 && raw1 < 200) begin

sum1 <= sum1 + raw1;

count1 <= count1 + 1;

if (count1 == 3) begin

dist1 <= (sum1 + raw1) >> 2;

sum1 <= 0; count1 <= 0;

end

end

if (measure2 && raw2 < 200) begin

sum2 <= sum2 + raw2;

count2 <= count2 + 1;

if (count2 == 3) begin

dist2 <= (sum2 + raw2) >> 2;

sum2 <= 0; count2 <= 0;

end

end

if (measure3 && raw3 < 200) begin

sum3 <= sum3 + raw3;

count3 <= count3 + 1;

if (count3 == 3) begin

dist3 <= (sum3 + raw3) >> 2;

sum3 <= 0; count3 <= 0;

end

end

end

// -----------------------------------------

// 3.1 Out-of-range check

// -----------------------------------------

parameter MAX_DIST = 16'd200;

reg out_of_range = 0;

always @(posedge int_osc) begin

if (dist1 > MAX_DIST || dist2 > MAX_DIST || dist3 > MAX_DIST)

out_of_range <= 1;

else

out_of_range <= 0;

end

// -----------------------------------------

// 4. PWM Motor Speed Control with Bilateral PD

// -----------------------------------------

parameter BASE = 90; // Increased base speed

parameter WALLP = 18;

parameter WALLD = 10;

parameter MAXCORR = 30;

parameter TURN_PWM = 30;

parameter PWM_MAX=90;

parameter PWM_MIN=30; // Increased turn speed

reg signed [15:0] err = 0, prev_err = 0, corr = 0;

reg [7:0] pwm_left = BASE, pwm_right = BASE;

reg [7:0] pwm_counter = 0;

reg pwm_a = 0, pwm_b = 0;

reg [23:0] pd_blink_counter = 0;

reg led2_state = 0;

always @(posedge int_osc) begin

if (!turning && !wait_turn && AIN1 == 0 && AIN2 == 1 && BIN1 == 0 && BIN2 == 1) begin

// Bilateral wall-following: balance between right and left walls

err <= dist1 - dist3;

if (err > -2 && err < 2)

corr <= 0;

else

corr <= ((WALLP * err + WALLD * (err - prev_err)) >>> 2);

prev_err <= err;

if (corr > MAXCORR) corr <= MAXCORR;

if (corr < -MAXCORR) corr <= -MAXCORR;

if (corr > 0) begin

pwm_left <= (BASE + (corr >>> 1) > PWM_MAX) ? PWM_MAX : BASE + (corr >>> 1);

pwm_right <= (BASE - corr < PWM_MIN) ? PWM_MIN : BASE - corr;

end else begin

pwm_left <= (BASE + corr < PWM_MIN) ? PWM_MIN : BASE + corr;

pwm_right <= (BASE - (corr >>> 1) > PWM_MAX) ? PWM_MAX : BASE - (corr >>> 1);

end

pd_blink_counter <= pd_blink_counter + (corr[15] ? -corr : corr);

if (pd_blink_counter > 100000) begin

led2_state <= ~led2_state;

pd_blink_counter <= 0;

end

end else begin

pwm_left <= TURN_PWM;

pwm_right <= TURN_PWM;

led2_state <= 0;

pd_blink_counter <= 0;

end

end

always @(posedge int_osc) begin

pwm_counter <= pwm_counter + 1;

pwm_a <= (pwm_counter < pwm_left);

pwm_b <= (pwm_counter < pwm_right);

end

assign PWMA = pwm_a;

assign PWMB = pwm_b;

// -----------------------------------------

// 5. Movement Logic - Flag-based FSM

// -----------------------------------------

parameter THRESH = 16'd4; // Adjusted threshold

parameter HYST = 16'd2;

parameter TURN_TIME = 24'd3600000; // Adjusted for 6 MHz: ~0.6 seconds

parameter UTURN_TIME = 24'd6000000; // Adjusted for 6 MHz: ~1.0 seconds

parameter MARGIN = 16'd4;

reg [23:0] turn_timer = 0;

reg turning = 0;

reg [1:0] dir = 0;

reg wait_turn = 0;

reg [23:0] pre_turn_delay = 0;

always @(posedge int_osc) begin

led1 <= (dist2 < THRESH);

led2 <= led2_state;

led3 <= (dist3 >= (THRESH + HYST + MARGIN));

if (turning) begin

turn_timer <= turn_timer + 1;

case (dir)

2'b01: begin

AIN1 <= 0; AIN2 <= 1;

BIN1 <= 1; BIN2 <= 0; end // Right turn

2'b10: begin

AIN1 <= 1; AIN2 <= 0;

BIN1 <= 0; BIN2 <= 1; end // Left turn

2'b11: begin

AIN1 <= 0; AIN2 <= 1;

BIN1 <= 1; BIN2 <= 0; end // U-turn

default: begin

AIN1 <= 0; AIN2 <= 0;

BIN1 <= 0; BIN2 <= 0; end

endcase

if (turn_timer >= ((dir == 2'b11) ? UTURN_TIME : TURN_TIME)) begin

turning <= 0;

turn_timer <= 0;

end

end else begin

if (out_of_range) begin

AIN1 <= 0; AIN2 <= 0;

BIN1 <= 0; BIN2 <= 0;

end else if (!wait_turn) begin

if ((dist1 >= (THRESH + HYST + MARGIN) && dist3 <= (THRESH + HYST + MARGIN) && dist2 <= (THRESH + HYST + MARGIN))||

(dist1 >= (THRESH + HYST + MARGIN) && dist3 <= (THRESH + HYST + MARGIN) && dist2 >= (THRESH + HYST + MARGIN))||

(dist1 >= (THRESH + HYST + MARGIN) && dist3 >= (THRESH + HYST + MARGIN) && dist2 >= (THRESH + HYST + MARGIN))||

(dist1 >= (THRESH + HYST + MARGIN) && dist3 >= (THRESH + HYST + MARGIN) && dist2 <= (THRESH + HYST + MARGIN ))) begin

wait_turn <= 1;

dir <= 2'b01;

pre_turn_delay <= 0; // Turn right

end

else if (dist1 <= (THRESH + HYST + MARGIN) && dist3 <= (THRESH + HYST + MARGIN) && dist2 >= (THRESH + HYST + MARGIN)) begin

AIN1 <= 0; AIN2 <= 1;

BIN1 <= 0; BIN2 <= 1;//go forward

end

else if (dist1 <= (THRESH + HYST + MARGIN) && dist3 >= (THRESH + HYST + MARGIN) && dist2 >= (THRESH + HYST + MARGIN)) begin

AIN1 <= 0; AIN2 <= 1;

BIN1 <= 0; BIN2 <= 1;//go forward

end

else if (dist1 <= (THRESH + HYST + MARGIN) && dist3 >= (THRESH + HYST + MARGIN) && dist2 <= (THRESH + HYST + MARGIN)) begin

wait_turn <= 1;

dir <= 2'b10;

pre_turn_delay <= 0; // Turn left

end

else if (dist1 <= (THRESH + HYST + MARGIN) && dist3 >= (THRESH + HYST + MARGIN) && dist2 <= (THRESH + HYST + MARGIN))begin

wait_turn <= 1;

dir <= 2'b11;

pre_turn_delay <= 0; // U-turn if both blocked

end

end

else begin

// Wait state before turning

AIN1 <= 0; AIN2 <= 0;

BIN1 <= 0; BIN2 <= 0;

pre_turn_delay <= pre_turn_delay + 1;

if (pre_turn_delay >= 24'd3000_000) begin // 0.5 second delay at 6 MHz

turning <= 1;

wait_turn <= 0;

pre_turn_delay <= 0;

turn_timer <= 0;

end

end

end

end

endmodule

Resource Utilization

⚙️ Resource Utilization Workflow

The following commands were used to synthesize the design and generate the resource utilization report:

# Step 1: Start Yosys

yosys

# Step 2: Run synthesis for the iCE40 FPGA family

synth_ice40 -top top_module_name -json out.json

Replace

top_module_namewith the name of your top module.

Final Output – Working Bot Demo

🐢 23% Speed Demo

▶️ Watch Video Initial test at 23% speed to verify wall-following and obstacle detection.

⚙️ 35% Speed Demo – Test Run 1

▶️ Watch Video First performance run at 35% speed to test navigation accuracy and speed handling.

⚙️ 35% Speed Demo – Test Run 2

▶️ Watch Video Second 35% speed test to demonstrate stability and route correction.

Project Recognition

Our Maze Solver Bot, developed entirely using the VSDSquadron FPGA platform, was officially recognized for its innovation and practical hardware implementation. This accomplishment was achieved by our team and has been featured in prominent LinkedIn posts showcasing FPGA-based robotics.

🏆 Featured Mentions

Project Authors

This project was designed, developed, and documented by the following contributors:

| S.No | Name | GitHub Profile | LinkedIn Profile |

|---|---|---|---|

| 1 | Elango Sekar | github.com/eceelango | linkedin.com/in/elango-sekar-8973b958 |

| 2 | Gowtham | github.com/gowthamnow | linkedin.com/in/gowtham-t-73a2b7299 |

| 3 | Dhanasri Anbalagan | github.com/DHANASRI-A | linkedin.com/in/dhanasri-anbalagan-0a5043360 |